In a process as dynamic as distilleries, purity and time are vital. Streamline your cleaning needs while saving water and time.

In addition to having the largest selection of sanitary tank cleaners, you can count on Spraying Systems Co. to provide local service and support. Need help with selection assistance? Interested in a trial prior to purchase? Challenged by stubborn residue? Our spray specialists are standing by and ready to help.

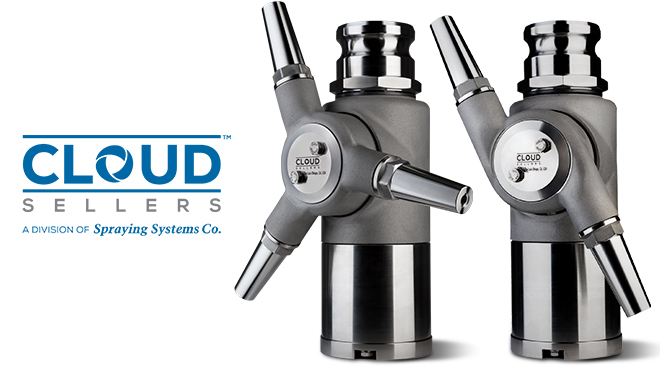

Tank Cleaning Equipment

The Cloud-Sellers® 360 Fluid-driven Tank Cleaner for tanks up to 100’ (30 m) in diameter is the most durable and reliable tank cleaning machine on the market, combining all the features needed to handle the most serious tank cleaning problems in your distillery.

- All units are built-to-order, lightweight for easy portability, and compact to fit in small tank openings

- Choice of dual- or triple-nozzle fluid-driven hubs

- High-impact, high-efficiency tank cleaning machine for hard-to-remove residues

- Outperforms other fluid-driven units – more consistent impact over the entire pressure range

- Superior service and maintenance plans available

Learn more about the Cloud-Sellers 360 Tank Cleaner

The 15HP Pump Cart high-pressure, high-volume unit, is designed to maximize the impact of your tank cleaning machine. We can save time and money and improve employee safety while ensuring optimal fluid transfer, reducing operational costs, and increasing productivity.

When it comes to tank cleaning and sanitizing, many companies are unwittingly costing themselves significant amounts of time and money due to one hidden problem: low pump pressure. Tank cleaning operations using less than 100 PSI result in running equipment longer, but longer run times come at a cost. Time is money. Running a pump at maximum output for extended periods will require more maintenance, a greater chance of complete breakdowns, and expensive repairs. Our pump cart can solve these problems. The 15HP pump cart uses a Waukesha model #C218 sanitary centrifugal pump and is mounted on a PEI stainless steel 4-wheel pump cart with 50’ of power cord.

Innovative Tank Cleaning Solutions for Distilleries

Our specialized tank cleaning equipment is engineered to meet the stringent cleaning and sanitation requirements of distilleries. Designed for efficiency, it ensures deep, reliable cleaning while minimizing water usage and reducing overall cleaning time. From fermentation tanks to spirit stills and other processing vessels, our solutions deliver exceptional performance and operational efficiency.

Key Features of Our Tank Cleaners:

- Compact designs that fit small tank openings

- High-impact cleaning power for tough residues like oils, sugars, and mineral deposits

- Reduced cleaning cycles to maximize production uptime

- Options for dual, triple or four nozzle configurations for customized solutions

Factory Maintenance Service

Send your spraying unit to a Spraying Systems Co. service center for prompt, dependable maintenance. With turnaround times as fast as 48 hours, we help minimize downtime and keep your distillery operations running smoothly.

Explore Tank Cleaning Maintenance Service

Cleaning Guns

CU150A GunJet® spray guns offer high-impact, low-pressure versatile performance with a variety of spray patterns. Specially designed handles will improve control used along with the optional swivel connectors with trigger lock which will reduce operator fatigue.

Our hose reel will make your job easier. Your hose will always remain connected with unrestricted flow at minimum pressure loss. Available as spring or manual rewind. We also have flexible and lightweight hoses available to fit every need.

See the full line of GunJet spray guns

Bottle Drying

Are you having problems with your current bottling process? With the right air knife package, water can be removed from the domes of empty cans between washer stages without knocking them over. For filled bottles and cans even the smallest drops can be removed.

WindJet® Air Knives have a unique design that directs a high volume of air out of the knife in a straight, uniform, stream. Consistent control of the air stream along the length of the knife combined with various blower output options makes it possible to effectively blow-off and dry-off any bottle or can design for a wide variety of applications.

See the full line of WindJet nozzles

Superior Service with Local Spray Experts Right Where You Need One

Need technical support from our team? Just tell us about your application and the specific issues you’re having. We’ll work with you to help you overcome the challenge. Many of our products are American Made so we can quickly order new parts to get your facility up and running.