The Critical Role of Spray Drying in Dairy Processing

Spray drying is a critical process in dairy production, converting liquid dairy products such as milk, whey, and cream into stable, high-quality powders for a variety of applications. Achieving consistent droplet size, moisture content, and bulk density is essential to ensuring product uniformity, efficiency, and compliance with food safety standards.

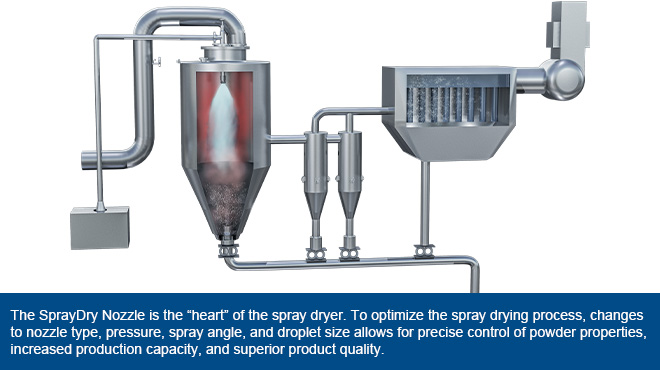

For decades, Spraying Systems Co. has been at the forefront of spray drying innovation, pioneering advanced SprayDry® nozzles to optimize atomization, improve yield, and reduce waste. Each spray drying tower operates under unique conditions, making precise nozzle selection and system optimization key to maintaining uniform powder characteristics while minimizing energy consumption and production downtime.

Spray-Dried Dairy Powders Using Spray Nozzle Technology

Overcoming the Challenges of Spray Drying in Dairy Processing

Don’t Struggle to Meet Production Targets

Dairy processors often face low production rates and underperforming dryers due to inefficient or incorrect nozzle setups. The SprayDry® nozzle product line offers the broadest range of designs in the industry, each

specifically engineered to meet the demands of dairy applications. Selecting the right nozzle design and operating parameters is essential for maintaining peak dryer performance. From swirl chamber nozzles that improve free passage, to slotted core nozzles for finer droplets, to multi-orifice nozzles that boost production without requiring additional capital investment, we have a tailored solution to keep your operations running smoothly.

Stop Product Loss and Improve Yield

Powder loss to dryer walls or the baghouse is a common issue in dairy powder production. Poor atomization or incorrect nozzle sizing can leave particles under-dried or over-dried, leading to waste and quality concerns. SprayDry® engineers work with your team to optimize spray angle, droplet size, and flowrate, ensuring powder stays airborne and dries efficiently, improving both yield and quality.

Achieve Specific Bulk Density Requirements

Out-of-spec and inconsistent bulk density can disrupt downstream processes like packaging and reconstitution. SprayDry® nozzles give you control over droplet size, and therefore particle size and bulk density, through optimized nozzle design and operating parameters. Generate larger, denser particles with the SV nozzle, or finer particles with the SB or SK series, to meet tight spec requirements. Achieving the proper bulk

density results in high product quality, efficient packaging, smooth processing, and cost-effective operations.

Reduce Bearding and Fire Risk in Dairy Plants

Bearding and product buildup around the nozzle can introduce serious safety risks, especially with dairy ingredients that are prone to caramelization or ignition. Our anti-bearding nozzles, designed with different

geometries, are optimized to resist buildup and minimize this risk. Proper nozzle selection and placement also reduce cleaning frequency and enhance overall plant safety.

Combat Clogging and Rapid Wear in High-Solids Formulas

High fat and protein content in dairy products often leads to nozzle clogging, CIP challenges, and costly wear. SprayDry™ nozzles are engineered with Maximum Free Passage technology to reduce blockages and improve spray consistency. Our tungsten carbide wear components, available in multiple grades, are proven to withstand the high pressures and abrasive characteristics of dairy feedstocks, helping you cut downtime and extend service life.

Learn How a Dairy Manufacturer Improved Safety, Reduced Waste and Increased Annual Revenue by more than US$2.5 million.

Show me how

Proven Solutions from Spraying Systems Co.

Achieving consistent powder quality, minimizing downtime, and maximizing efficiency starts with the right spray drying nozzles. As the final component in transforming liquid dairy products into powder, nozzles play a critical role in your drying process.

At Spraying Systems Co., we offer the broadest range of SprayDry® nozzles, designed to optimize atomization, droplet size distribution, and wear resistance. With both slotted core and swirlchamber designs, our precision engineered solutions ensure uniform powder consistency, superior production efficiency, and long-lasting performance to meet the unique demands of dairy spray drying.

SprayDry® Nozzle Selector View Performance Data (PDF)

Key Features & Benefits of SprayDry® Nozzles

Spray drying in dairy processing requires precise atomization and durable nozzles to withstand abrasive powders, high pressures, and long production cycles. Our SprayDry® nozzles offer:

-

Optimized Droplet Control for Powder Consistency: Achieving a consistent drop size distribution ensures even moisture content, uniform particle size, and stable bulk density, preventing product variability and rework

-

Maximum Free Passage (MFP) Design for Clog Prevention: Dairy slurries with high fat and protein content can lead to frequent nozzle clogging and uneven spray patterns. Our MFP nozzles are engineered to reduce blockages, extending production runs and reducing costs.

-

Tungsten Carbide Wear Resistance for Longevity: Spray drying abrasive dairy slurry at high pressures causes excessive nozzle wear. Our tungsten carbide nozzles (“M” and “Y” grades) are built to withstand harsh conditions, extending operational life and reducing frequent part replacements.

-

Food-Grade Materials and Regulatory Compliance: All SprayDry® nozzles are made from food-compliant materials, ensuring they meet stringent hygiene and safety regulations required in dairy processing.

-

Anti-Bearding & Check Valve Options for Reduced Waste: Options such as anti-bearding caps and check valves further reduce dripping, buildup, and contamination risks, maintaining optimal nozzle performance throughout production.

-

Easy Maintenance: Hand-tightened, easy-to-disassemble designs shorten maintenance windows, allowing you to get production back online faster and reduce labor costs.

By leveraging advanced spray technology, dairy processors can achieve higher efficiency, superior powder quality, and reduced operational costs.

Expert Guidance & Ongoing Support

At Spraying Systems Co., we go beyond simply providing nozzles—we deliver technical expertise, field support, and hands-on collaboration to ensure your spray drying process runs at peak performance. From on-site evaluations to custom lunch & learns, our team partners with you to solve challenges, optimize results, and drive continuous improvement.

FAQs

Sustainable Practices with Spraying Systems Co.

Spraying Systems Co. is committed to helping industries adopt sustainable practices by optimizing water usage, reducing cleaning waste, and minimizing environmental impact. Schedule a sustainability assessment to discover cost-saving opportunities and improve resource efficiency with our advanced spray technology.

Contact a sustainability expert