POWER GENERATION

Natural Gas

Maximize gas turbine output, reduce emissions, and optimize efficiency with Spraying Systems Co.’s high-performance spray solutions. Our advanced turbine inlet cooling and NOx control systems are engineered to help natural gas power plants achieve higher energy production, lower fuel consumption, and regulatory compliance.

Maximize Efficiency in Natural Gas Power Generation

At Spraying Systems Co., we understand that efficiency and emissions control are critical for high-performing natural gas power plants. Our advanced spray solutions optimize turbine cooling, enhance energy output, and ensure regulatory compliance, all while reducing operational costs and environmental impact.

From turbine inlet cooling to NOx emissions control, our precision-engineered spray nozzles and automated systems deliver superior atomization, precise fluid control, and unmatched reliability. With expert support and industry-leading technology, we help power plants maximize output, minimize waste, and stay ahead of emissions regulations—so you can focus on delivering reliable energy while we handle the spray technology challenges.

Industry Challenges in Natural Gas Power Generation

The natural gas power generation industry faces unique challenges in maintaining turbine efficiency, controlling emissions, and optimizing cooling performance. Without the right spray solutions, facilities risk reduced power output, increased operational costs, and environmental compliance issues.

Key Challenges in Natural Gas Power Generation

- Heat-Related Efficiency Losses: Gas turbine performance drops as ambient temperatures rise, reducing power output

- Inconsistent Air Cooling: Traditional cooling methods often fail to effectively reduce inlet temperatures, leading to inefficient combustion

- NOx Emissions Compliance: Regulatory standards require precise scrubbing technology to control NOx emissions while maintaining combustion efficiency

- Water Usage & Sustainability Concerns: Inlet cooling requires high water volumes, increasing operational costs and environmental impact

- System Maintenance & Downtime: Nozzles used in cooling and emissions systems face clogging and wear, leading to poor efficiencies and potential system failures

Our Solutions for Natural Gas Plants

Key Applications in Natural Gas Power Generation

Turbine Inlet Cooling for Maximum Power Output

Gas turbines perform best when the air entering the compressor is cool and dense. Our HP FogJet® Nozzles create ultra-fine droplets, maximizing evaporation and reducing air temperatures, leading to:

- Higher energy output without additional fuel consumption

- Lower operating costs by improving compressor efficiency

- Reliable cooling even in extreme ambient temperatures

Wet Compression for Additional Power Gain

Boost gas turbine performance with wet compression, which enhances inlet air cooling, humidity control, and density for greater energy output. Our multipoint spray nozzles inject high volumes of ultra-fine droplets, ensuring efficient evaporation even in space-constrained systems.

- Increased power output in all ambient conditions

- Lower capital costs compared to other performance upgrades

- Seamless integration alongside turbine inlet cooling for enhanced efficiency

NOx Emissions Control for Regulatory Compliance

Meeting NOx emissions regulations requires precise ammonia or urea injection into the gas stream. Our FloMax® Air Atomizing Nozzles ensure:

- Uniform droplet size for effective NOx reduction

- Optimized spray patterns for maximum catalyst efficiency

- Reduce compressed air usage, lowering operational costs

Supporting Accessories for Complete System Optimization

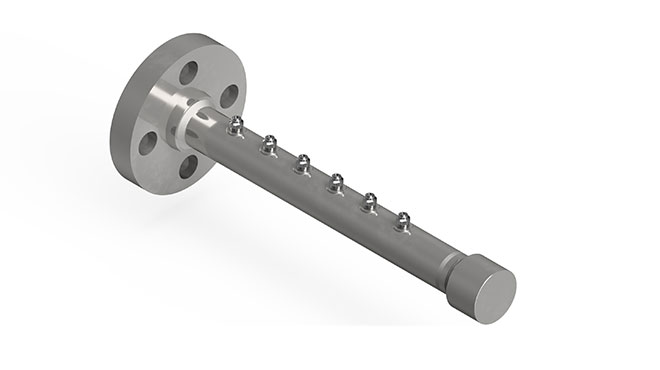

A complete turbine cooling and emissions control system requires precision-engineered FlowDrill and Spray Lance components to ensure efficient fluid distribution, durability, and seamless integration. These fabricated solutions are designed to withstand high-pressure environments while optimizing system performance.

- Efficient fluid distribution for turbine cooling and NOx reduction

- Durable design for longer system life and easier maintenance

- ASME 31.1 & 31.3 compliant for high-pressure, high-temperature use

Automated Control with AutoJet® Systems

AutoJet® Systems deliver real-time monitoring and precision control over spray processes, ensuring:

- Automated nozzle performance adjustments for consistent efficiency

- Reduced water and chemical waste through precise dosing

- Seamless integration with existing plant control systems

Sustainable Practices with Spraying Systems Co.

Spraying Systems Co. is committed to helping industries adopt sustainable practices by optimizing water usage, reducing cleaning waste, and minimizing environmental impact. Schedule a sustainability assessment to discover cost-saving opportunities and improve resource efficiency with our advanced spray technology.

Contact a sustainability expert

Get Started Today

Spraying Systems Co. is dedicated to helping power plants improve efficiency, lower emissions, and optimize energy output. Our proven spray technology solutions provide long-term value and rapid ROI for turbine cooling and NOx reduction applications.

Special Offer: Free On-Site Trial

Experience the benefits of precision-engineered spray technology with a free on-site trial. Optimize your turbine cooling and emissions control while reducing operational costs. Let us help you enhance efficiency, maximize power output, and ensure compliance with industry-leading solutions.