SANITARY TANK CLEANING

If your operations require the use of sanitary equipment to clean tanks, totes, vats or other process vessels, you’ll find what you need in our line of TankJet® equipment. All of our sanitary tank cleaners meet the criteria for hygienic design and feature food contact materials of construction.

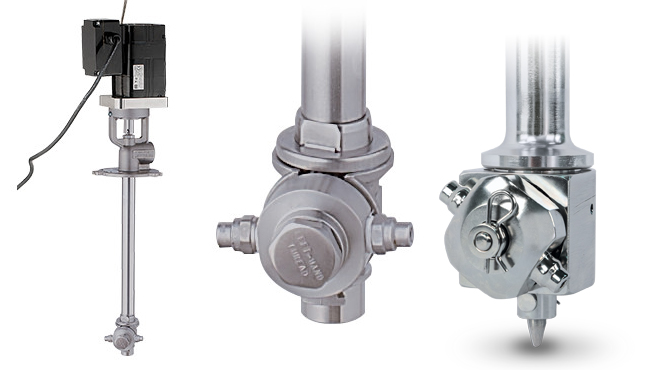

Many of our tank cleaners are 3-A Sanitary Standard 78-03 certified. Our TankJet 78 and 78M are the only multi-axis high-impact tank cleaners with 3-A certification. Other 3-A certified products include medium- and low-impact tank cleaning nozzles and spray balls.

CLEANING POWER GUIDELINES

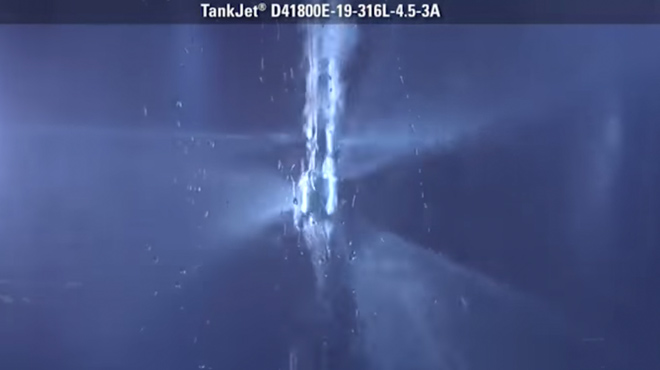

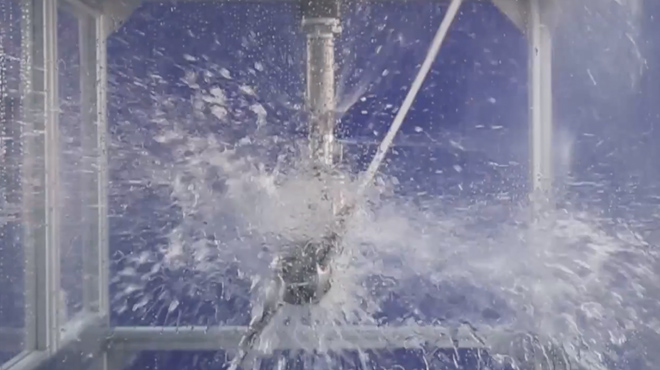

High-impact cleaning is required to remove stubborn residues such as layers of a dried substance. Tank cleaners in this category generally use high pressure and/or high flow and spin at slow rotational speeds to maintain high impact. Solid stream nozzles are used to maximize impact.

Medium-impact cleaning is required when good impingement is needed to remove residues. Tank cleaners that provide medium impact generally use solid stream nozzles at medium flows and pressures. Rotational speed is slightly faster than high impact tank cleaners but much slower than free-spinning nozzles to ensure adequate impact on target areas.

Rinsing is used when distributing cleaning solution throughout the tank without impact provides sufficient cleaning. Rinsing nozzles are typically free-spinning or stationary spray balls.

Sanitary TankJet Tank Cleaner Overview |

|||||||||

| Sanitary Nozzle | Max. Tank Dia. ft (m) |

Operating Principle | Impact | 3-A Sanitary Standard 78-03 Certified |

|||||

| TANKJET 78 | 40 (14) | Fluid-driven turbine | High | • | |||||

| TANKJET 78M | 25 (7.6) | Fluid-driven turbine | High | • | |||||

| TANKJET 28500R | 18 (5.5) | Fluid-driven reactionary force | Medium | • | |||||

| TANKJET D41800-3A | 12 (3.7) | Fluid-driven constant speed | Low | • | |||||

| TANKJET 63225-3A SPRAY BALLS | 13 (4) | Fixed stationary | Low | • | |||||

| AA190HYG | 45 (13.7) | Motor-driven | High | ||||||

| TANKJET 75H | 30 (9.1) | Fluid-driven turbine | High | ||||||

| TANKJET 80H | 50 (15.2) | Fluid-driven turbine | High | ||||||

Sustainable Practices with Spraying Systems Co.

Spraying Systems Co. is committed to helping industries adopt sustainable practices by optimizing water usage, reducing cleaning waste, and minimizing environmental impact. Schedule a sustainability assessment to discover cost-saving opportunities and improve resource efficiency with our advanced spray technology.

Contact a sustainability expert