TANK CLEANING FOR ETHANOL PRODUCTION

Comprehensive Product Line to Keep Ethanol Plants at Optimal Efficiency

WE'RE THERE FOR THE ETHANOL INDUSTRY

Now that Spraying Systems Co. has acquired Cloud-Sellers, ethanol production gets the best of both worlds: an industry-standard product that does the job better, and a vast team of experts who can help optimize and maintain production like no one else.

You have access to all of Spraying Systems Co., including our 85 years of history, global impact and local field offices. From product innovation to sustainability initiatives, we always have our eye on the future.

Book an On-site Assessment Contact Us

WHY SPRAYING SYSTEMS CO.?

BOOTS ON THE GROUND

No one else has the footprint we do. Wherever you are in the U.S., your spray expert is nearby.

STATESIDE DESIGN & ENGINEERING

Home-grown innovation in the Chicago area, with a comprehensive and effective product catalog.

DEEP ETHANOL EXPERTISE

Our team acts as an extension of yours, solving problems the right way the first time.

SPRAY TECHNOLOGY PROS

We help you maximize the impact of your spray technology, staying efficient at all times.

ETHANOL AT A GLANCE

The ethanol industry is close-knit and collaborative, with plants often working together to improve processes and productivity.

If you work in ethanol production, there are not enough hours in the day to get everything done. So, regarding spray technology inside fermentation tanks, it’s not uncommon to hope things are working and move onto other tasks. This is where Spraying Systems Co. proves lasting value. Our spray optimization, preventive maintenance and troubleshooting can help you save big on resources and prevent downtime-related headaches.

FUELING TANK HEALTH

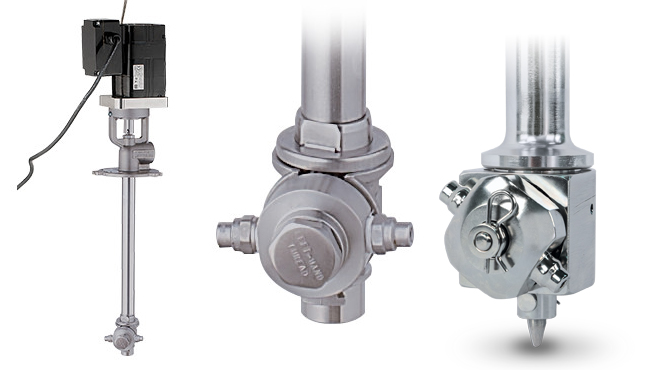

Cloud-Sellers® 360

Incredible Impact Across Multiple Pressure Ranges

Two questions about your fermentation tanks: are they being cleaned properly, and is your system as efficient as it can be? Spraying Systems can help you answer both of those questions. We help you find the ideal configurations that promote effective and reliable tank cleaning. The ideal configuration of the Cloud-Sellers 360 tank cleaning machine is determined by understating water quality, available liquid pressure, and tank geometry. These factors will determine gearbox selection, nozzle size, and rotational speed. Having the correct configuration extends the operational life of the tank cleaning machine.

- 2-or-3-nozzle configuration

- Designed for tanks up to 100 feet in diameter

- Gear ratio variations and gearbox designs

- Food-grade oil-lubricated or flow-through options

THE TANK CLEAN ROUTINE

No matter where your ethanol plant is located, you have a Spraying Systems Co. rep nearby and ready to work together on optimizing your tank cleaning system. Once you have the ideal system in place, remember: it will only remain optimized if you stay diligent with periodic maintenance. All told, you can save well over 50% on future repair costs with regular periodic maintenance. There are a few ways you can engage with this vital Spraying Systems service, so choose the one that’s right for you.